Hahlbrock

Company

We develop and manufacture geometrically sophisticated molded parts of the highest quality. The composite materials we design, with their outstanding surface and material properties, offer constructive advantages and expand the design possibilities.

- Consulting – Planning – Design

- Construction – Dimensioning

- Material selection and material optimization

- Model and mold making

- Mock-up – Prototyping

- Pre-series – small series – series production

- Component production by injection – hand laminate – fibre spraying – pressing

- Molded parts of all kinds on behalf of customers – GRP, CFRP and AFRP

Solutions

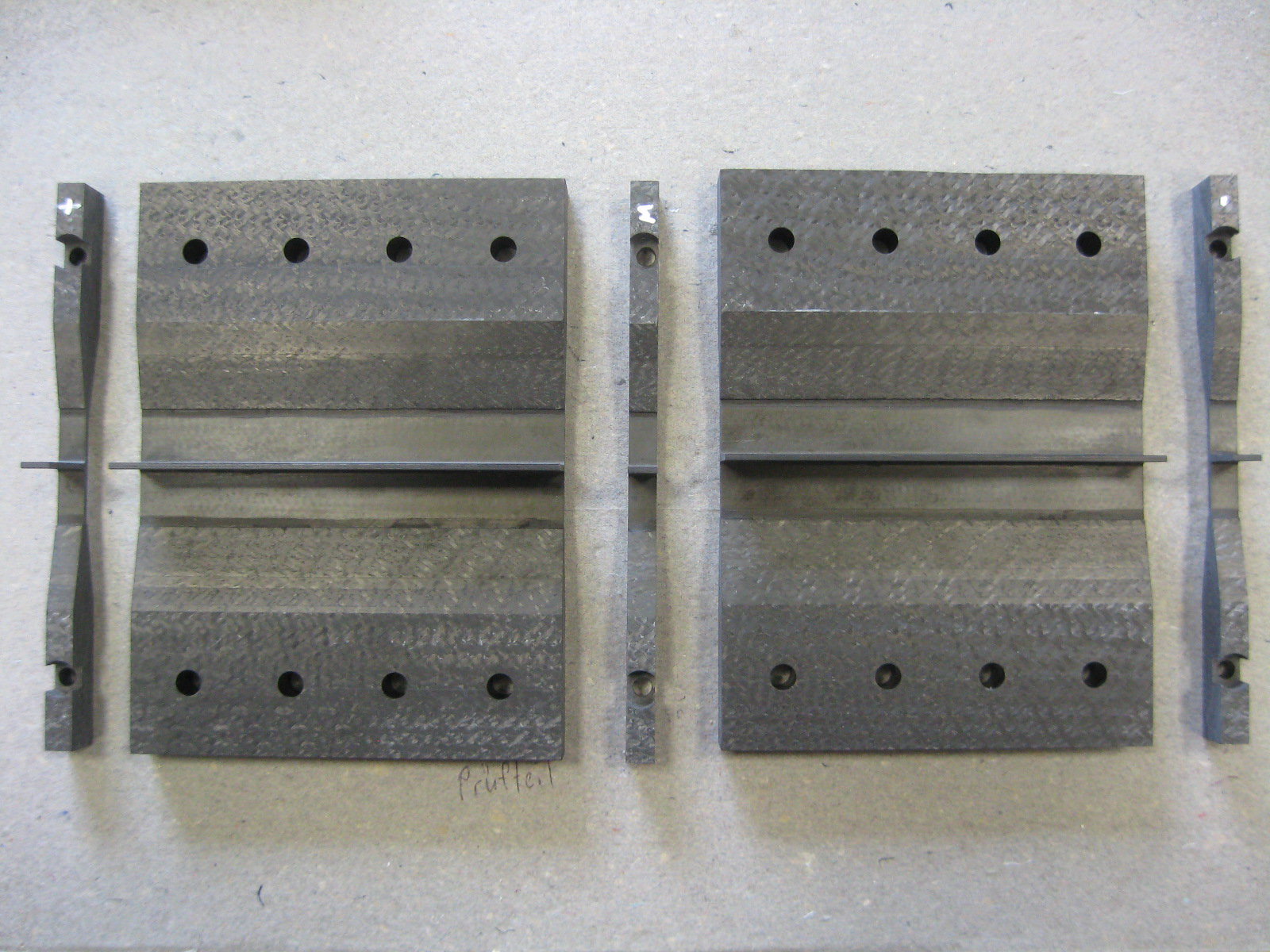

Mold and model making

Hahlbrock GmbH has an efficient model and mold making department – among other things through the latest CNC milling machine technology that works in a CAD-CAM network.

If you, as a user or manufacturer of molded parts made of fiber composite materials, are confronted daily with demands regarding the geometric complexity and molded precision of your products, we also offer you this capacity to expand your own production and component development:

- Master pattern and mold making in all modeling materials

- Formatting, drilling, cutting and final machining in five axis of fiber composite molded parts made of GFRP, AFRP and CFRP

- Capturing complex edge curves through teach-in programming

- Fast series processing and flexible conversion through tandem operation.

Solutions

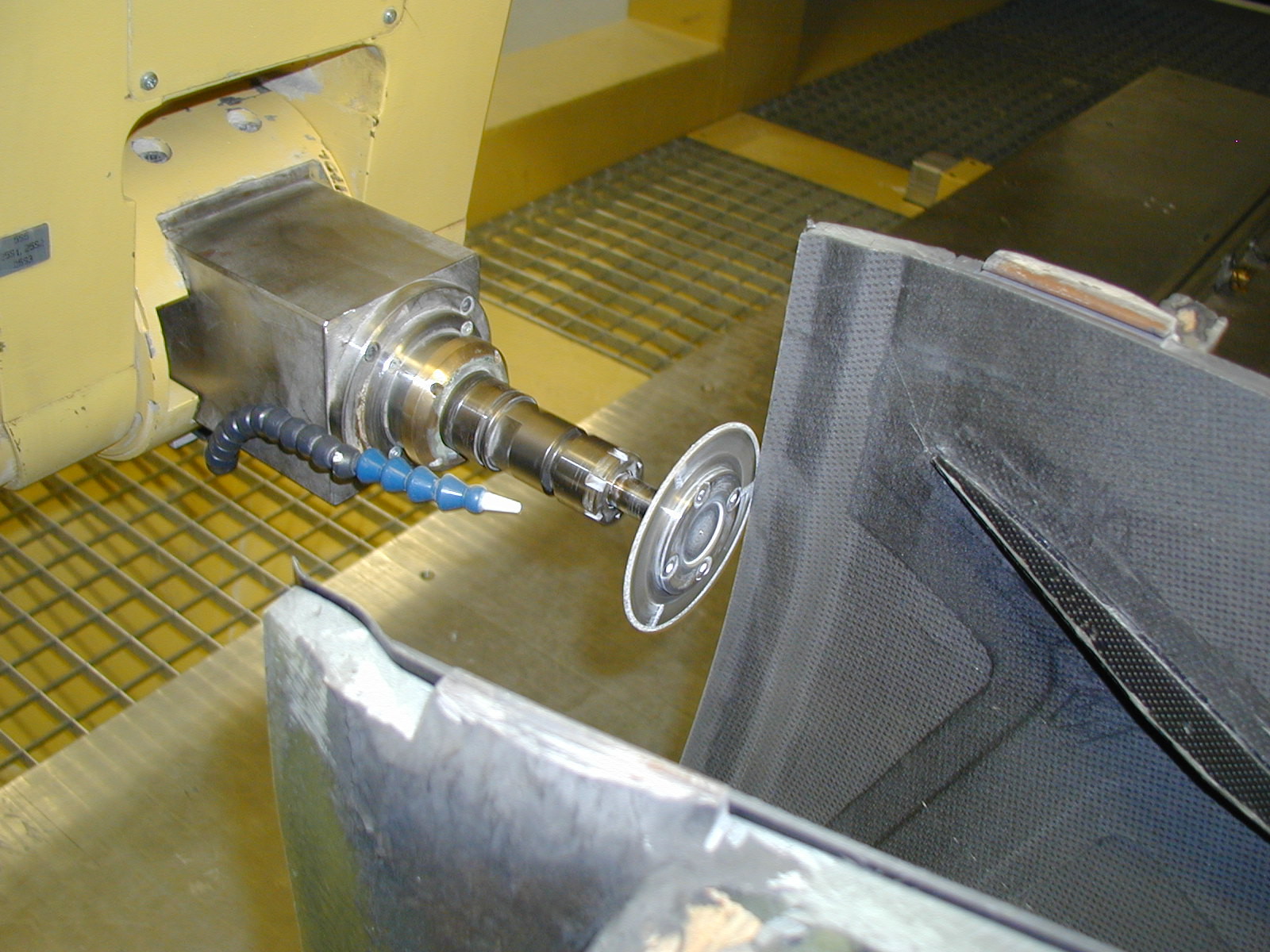

CFRP machining

Within the material group of fiber-reinforced plastics (FRP), carbon fiber-reinforced plastics (CFRP) occupy a special position due to their exceptional properties.

This affects both their mechanical properties and the parameters of a milling and drilling operation. Due to the high hardness and brittleness of the fibers in the material composite, it has proven to be particularly economical to machine these materials with wear-resistant diamond tools using the high-speed milling process (HSC).

Hahlbrock has many years of experience in the milling and drilling of CFRP molded parts. Due to their maximum travel distances in X / Y up to 5000 / 2500 mm, our HSC milling machines are also suitable for five-axis NC machining of large geometries.

Milling machines, controls and peripherals are specially designed for dry machining of electrically conductive C-fiber composites. The milling programs are created using a CAD-CAM system or alternatively using a teach-in process using a sample molding.

References exist primarily in the aviation industry and from suppliers to this market.

CNC milling, reverse engineering, molded part measurement (DE)