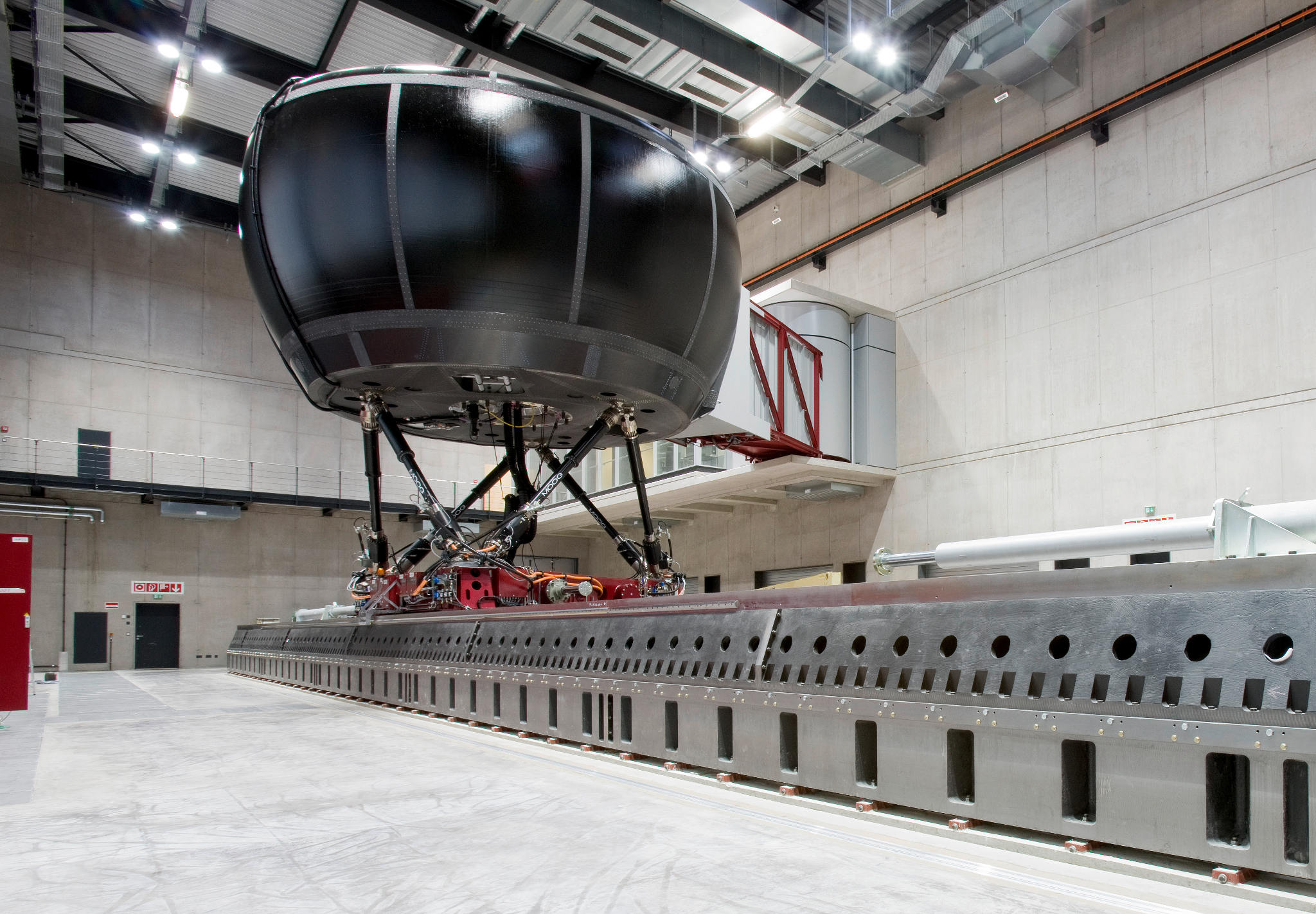

Hahlbrock manufactured the largest substructure of the new driving simulation system, the testing room made of carbon fiber reinforced plastic.

The simulator dome can accommodate a complete Mercedes vehicle (not just mock-ups); The 360° projection screen provides a realistic representation of road traffic. This testing room is housed as a hexapod with six movable supports.

To simulate highly dynamic driving processes, the goal was to develop a very light and at the same time stiff simulator dome.

CONSTRUCTION

- Round support platform with an attached spherical section as a projection surface

- Top end with a roof in the shape of a flat cone

- The roof supports the eight high-performance image projectors

- Door opening for bringing cars into the cathedral

GEOMETRY AND WEIGHT

- Spherical diameter, outside: 7.67m

- Spherical diameter, inside: 7.52m

- Spherical height: 3.00m

- Dome height with roof: 4.52m

- Dome width with gate: 7.81m

- Gate width: 2.68m

- Gate height: 2.49m

- Weight (without car): approx. 5.5t

MATERIALS

- Platform: Central cast aluminum element with radially attached molded parts made of carbon fiber reinforced plastic (CFRP)

- Dome jacket (spherical section): Fiber composite sandwich material, consisting of a core made of lightweight PVC foam and thin cover layers made of CFRP on both sides

- Dome roof: Roof cap also made of fiber composite sandwich material, radially stiffened with ribs and struts made of CFRP

MANUFACTURING PROCESS

The CFRP parts were manufactured using a vacuum-assisted resin injection process. Flat fabrics made of carbon fibers were placed in several dry layers in a mold and then impregnated with epoxy resin under vacuum. The composite of carbon fibers and the synthetic resin then hardened at temperatures of up to approx. 80°. After removing the hardened CFRP raw parts from the molding tools, the edges of the moldings were milled into their final contour using NC-controlled machines and, if necessary, drilled.

ASSEMBLY

The individual CFRP molded parts were glued together using an epoxy resin adhesive and riveted with around 24,000 special titanium rivets. The arrangement and alignment of the over 200 individual CFRP parts was carried out in NC-milled assembly devices, with individual parts being precisely adjusted using distance lasers. The accuracy of the spherical shells of the dome mantle was determined by laser scanning.

Installation location: Daimler development center MTC Sindelfingen

Production time: approx. 2 years

Delivery: February 2010 (including previous material testing phase)

Commissioning: October 2010

PROJECT IMAGES