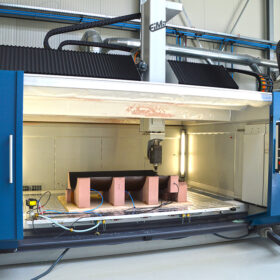

With the implementation of a large five axis milling machine Gamma-S from the manufacturer EiMa, Hahlbrock has now once again significantly increased its milling capacities.

The new portal milling machine, whose main axis travels X-Y-Z are 3.00 – 2.00 – 1.25 m, is, like the machines already installed, an HSC milling machine for dry machining of fiber-reinforced plastics (FRP) of all types, as well as tooling and wood materials. In addition, aluminum can also be effectively machined under minimum quantity lubrication.

The fully enclosed machine room and a powerful multi-sided dust extraction system are further features of the Gamma-S that specifically optimize the precise NC machining of FRP and hybrid FRP materials with aluminum or titanium sheet inserts.

Like the other milling machines at Hahlbrock, the new machine works in the CAD-CAM network as well as with programs created on the workpiece using the teach-in process. The integrated wireless probe and the self-calibration cycles enable precise NC machining operations that are usually less precise for large HSC machining centers.

MILLING MACHINE EIMA GAMMA S

Machine type: EiMa Maschinenbau GmbH

Machine type: Gamma S

Main axis length x / y / z: 3000 / 2000 / 1250 mm

Max. Traversing speeds x / y / z: X-Y: 60m/min; Z: 40m/min

Milling spindle: Omlat 15 kW

Spindle speed: 24.000 U/min

Tool holder: HSK63-F with switchable internal tool cooling

Milling head type: five axis fork head, with hydraulic. Round roof clamping

Machine control: Simunerik 840D sl

Accuracy class: 2

Equipment features:

- 12-fold tool changer, dust-tight encapsulated

- Fully enclosed machine workspace

- Individually switchable dust extractors on 3 sides

Accessories: radio measuring probe m+h 38.41